Condition Monitoring & Predictive Maintenance

We unlock these benefits for you and implement your predictive maintenance solution – from vision to condition monitoring to predictive maintenance.

Condition Monitoring & Predictive Maintenance

We unlock these benefits for you and implement your predictive maintenance solution – from vision to condition monitoring to predictive maintenance.

With eoda from vision to successful implementation

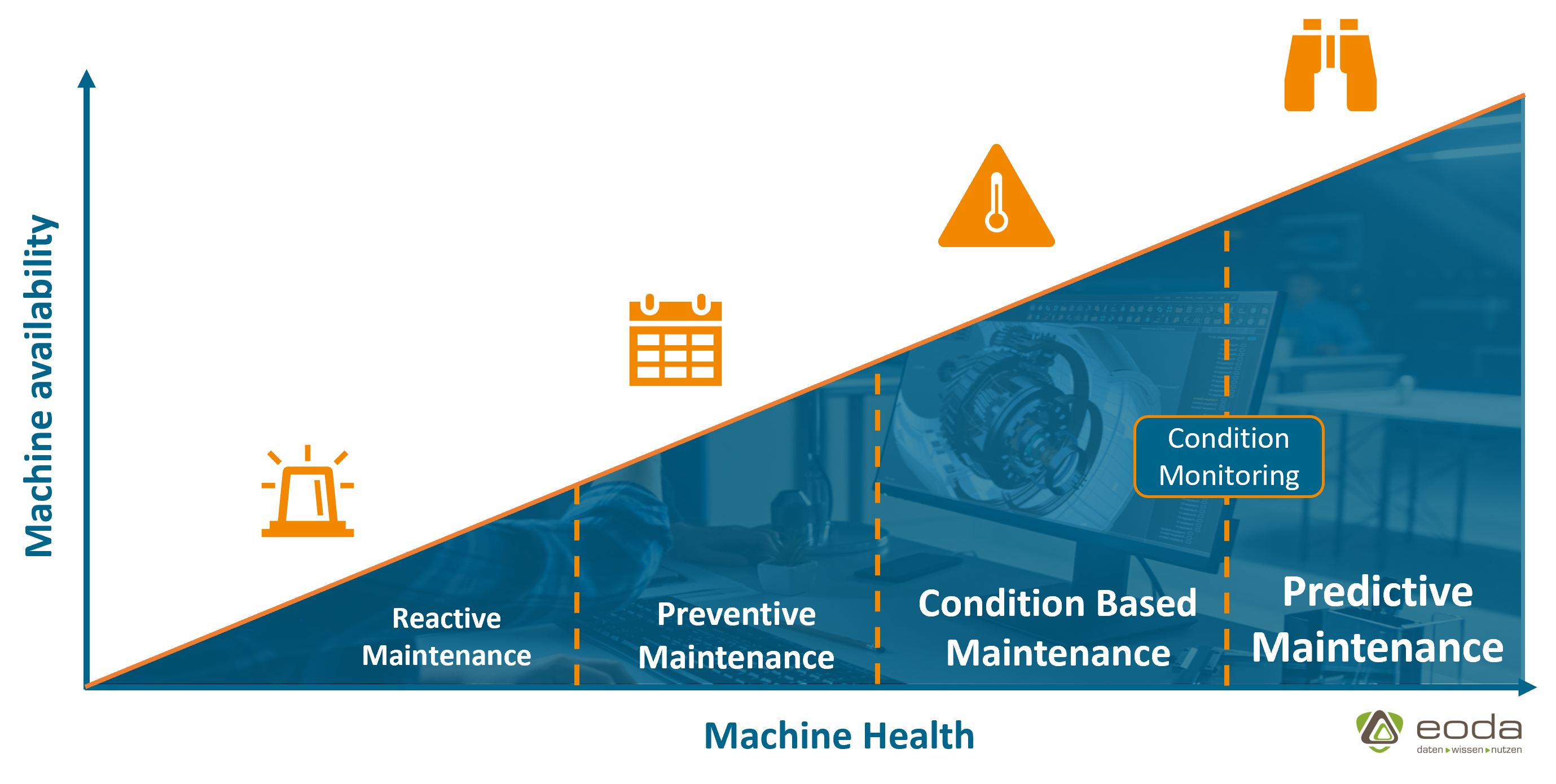

Higher machine availability, optimized maintenance processes and additional revenue opportunities through digital service offerings: Predictive maintenance stands for many benefits.

For more than 10 years, we have been the contact when it comes to successfully bringing artificial intelligence to machine and plant engineering.

„With YUNA eoda enables us to fix problems before they actually occur. Thanks to real-time data evaluation, we reduce downtime, optimize processes and increase machine availability at the same time.“

– Marco Holzer |Head of Product Management & Logistics Services | TRUMPF

The perfect starting point

Are you still very much in the early stages of condition monitoring and predictive maintenance, or are you already running your first AI initiatives? We have the right offer for your current AI maturity level.

Predictive Maintenance & Condition Monitoring: A selection of our references

TRUMPF: Predictive maintenance – TRUMPF Lasertechnik

Realization of the vision to generate business values from data - from knowledge transfer, to the development of a condition monitoring platform, to the development of analysis models.

Schenck Process: With predictive maintenance to new customer services:

Development of a "Health Indicator" with real-time information on machine condition to create a new service module.

WEISS Gruppe: With Condition Monitoring and Predictive Maintenance to the smart rotary indexing table for WEISS

Develop new digital service modules and increase component reliability through the consistent use and analysis of control data.

SMA: With digital twin and AI to smart services in solar energy

Building a digital twin to create smart services in solar energy - for example, predictive maintenance of photovoltaic systems.

We are member

Master the challenges on the way to predictive maintenance with us

IT-Security

The topics of IT security and data protection are the foundation of our work. As part of VIVAVIS AG, we keep a close eye on IT security infrastructure systems and create data solutions that can withstand the high demands of critical infrastructure systems.

IT-Infrastructure

The proper infrastructure is the cornerstone of successful AI initiatives. We have been developing and operating IT infrastructures for our customers ourselves for several years, creating the optimal conditions for sustainably successful AI initiatives.

Data Availability

(Sensor)-data is the starting point for predictive maintenance. But it doesn’t have to be “Big Data” to gain valuable insights. Before a project, we review your data inventory, identify the potential and develop options to – if necessary – further improve your data situation.

Get started now – we will guide you through!